After talking with @Tsingtao_1903, I think there's a Cool Guys Club in the works - not sure if it's limited to Texans or not.

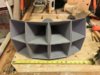

As for the WP designation, Tsingtao really knows what's up. Set the 12024 up on top of one of my Altec 9849's, using the driver and crossover from that unit. Looking forward to getting into some listening!

As for the WP designation, Tsingtao really knows what's up. Set the 12024 up on top of one of my Altec 9849's, using the driver and crossover from that unit. Looking forward to getting into some listening!