JP

Junior Member

They’re such beautifully made arms. My EPA-500 has the gummed up VTA like I’m sure most unrestored ones do. It made my other tonearns feel a bit toylike.

Later production units used silicone oil on the helicoid. As long as it's not too difficult to turn I leave it alone. Earlier ones with grease are an entirely different matter.

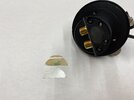

For this arm it was cleaning and re-lubing the AS knob, checking the bearings, and re-gluing the VTA adjustment ring. I typically always re-do that ring as the glue that was used turns to dust eventually.

They are fabulous arms. I hope to get back to my upgraded version soon.