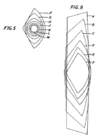

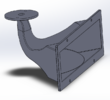

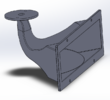

So, went down quite a number of rabbit holes with this project.... I really wanted to be able to create a model from scratch (using existing design features and dimensions) to understand better the fascinations surrounding the 32x horns. Spent quite a bit of time on an Altec 32C. Took careful measurements. Did numerous expansion calculations. Made models after models. Not one was satisfactory. Could not make the throat dimensions and geometries of the Altec 32C to fit Figure 5 in patent 197723 with regard to the throat expansions. (One of the two patents casted on WE 31A and 32A horns).

A few days ago, went back and read Chuck's post again.

electravolt.blogspot.com

electravolt.blogspot.com

Chuck made two important observations: 1) The original throat diameter is 0.76", and 2) For the 32C, Altec engineers lofted off the throat to where the cross section was the equivalent of 1" drivers. BAM, my earlier models were all too short since they were based on the 32C dimensions. There was not sufficient distance for the throat expansion from a circle (M) to a pie shape (F).

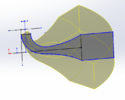

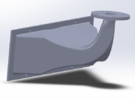

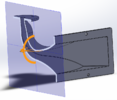

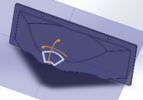

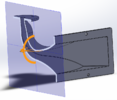

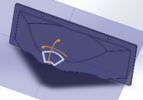

Went back and made some calculation as to what the "missing" length would be to expand from a 0.76" driver throat to an 1" driver throat. Turned out to be a little over 1". Added this distance back into the model. The extra distance allowed for much smoother transition from a round shape to a pie shape per Figure 5.

Cross section views of the transitions.

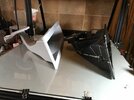

Was not easy. But, learned a few things. Hats off to WE engineers!

A few days ago, went back and read Chuck's post again.

The Tale of Three Horns... Variations of the Western Electric 32A Horn

audio, tube, horn loudspeaker, high efficiency, loudspeaker, turntables, vinyl, field coil,

Chuck made two important observations: 1) The original throat diameter is 0.76", and 2) For the 32C, Altec engineers lofted off the throat to where the cross section was the equivalent of 1" drivers. BAM, my earlier models were all too short since they were based on the 32C dimensions. There was not sufficient distance for the throat expansion from a circle (M) to a pie shape (F).

Went back and made some calculation as to what the "missing" length would be to expand from a 0.76" driver throat to an 1" driver throat. Turned out to be a little over 1". Added this distance back into the model. The extra distance allowed for much smoother transition from a round shape to a pie shape per Figure 5.

Cross section views of the transitions.

Was not easy. But, learned a few things. Hats off to WE engineers!