You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Interconnects

- Thread starter TubeHiFiNut

- Start date

Do It Yourself

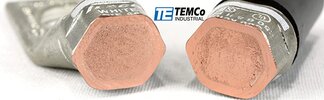

Mogami shielded two conductor (i.e., three in toto) with the cheap REAN Neutrik connectors -- yes, they're directional.

DSC_0722 (2) by Mark Hardy, on Flickr

DSC_0722 (2) by Mark Hardy, on Flickr

DSC_0722 (2) by Mark Hardy, on Flickr

DSC_0722 (2) by Mark Hardy, on FlickrThese are some seriously good interconnects. They use Connex “The Natural One” cable which is a shielded cable with twisted 22g stranded, tinned copper conductors and cotton insulation. (Connex is the PartsConnexion house brand). The plugs are ETI Link. For a 1m pair the total cost is less than $150.

I have made three pairs so far all with Link connectors. The short 1/2m pair in the pic is shielded for my SUT outputs. The others are unshielded. I ordered another 8m two months ago but PCX is presently back ordered. That will make a 4m pair that I can use for my main cables going to the power amps. It will have WBT Ag plugs.

The Connex/Link cables have replaced some very expensive Audio Note silver cables.

I have made three pairs so far all with Link connectors. The short 1/2m pair in the pic is shielded for my SUT outputs. The others are unshielded. I ordered another 8m two months ago but PCX is presently back ordered. That will make a 4m pair that I can use for my main cables going to the power amps. It will have WBT Ag plugs.

The Connex/Link cables have replaced some very expensive Audio Note silver cables.

Last edited:

I almost bought the parts for that Silver recipe from VH Audio, but changed my mind and built a different one Chris used to have on his site some years ago using a miniature coax cable called Pulsar Cu, and some Vampire C4X RCAs:I've built a number of DIY recipes.

My two favorites are

1) VH-Audio fine silver wire using his cotton insulated wire spiraled around his foamed teflon tubing. Silver Interconnect

2) VH-Audio using his V-Twist V-Twist

He's also now also got a silver version of that Pulsar mini coax that he says is competitive with most anything out there if using really good RCAs such as WBT NextGen Ag.

In the same parts order I did buy the V-Twist Cu-24 you mentioned above, and then for some reason I mothballed that project, it's still sitting in a parts bin somewhere. Hmmm, we're supposed to have an ice storm tomorrow, maybe I'll make a cable to celebrate President's Day?

I tried V-Twist a few years ago and really gave it the old college try by using it with KLE Absolute, WBT Next Gen Ag, and Switchcraft plugs, but it just didn’t match my tastes. One thing you should know is that V-Twist needs many hours of use to reach its full potential due to the Teflon. I stopped noticing changes after about 500 hours with the KLE plugs (and the plugs were already broken in).

One good thing about the V-Twist is it is super easy to terminate. And it is also very flexible so there’s no problem fitting the cable in tight spots or making sharp bends.

One good thing about the V-Twist is it is super easy to terminate. And it is also very flexible so there’s no problem fitting the cable in tight spots or making sharp bends.

Wow. I'm a firm believer in cable break-in, it doesn't take super human hearing to notice it, and I know what you mean about Teflon, but 500 hours is insane!I stopped noticing changes after about 500 hours with the KLE plugs (and the plugs were already broken in).

I'm going to use the ETI Research LINK gold plated copper RCAs with that V-Twist Cu24 wire.

And speaking of cable break-in, it took a bit over a week of steady listening for my first pair of Duelund DCA20ga (600V) with Switchcraft connectors to settle down enough to convince me to make a second pair. Not that pair #1 sounded bad initially, just (to my ears) a tad bright. But they're definitely rounding into shape now. Tons of detail, a lot less edge. Hence, pair #2:

I should probably quit while I'm ahead now but I can't see that happening; too many really cool suggestions left to try. Thanks, everybody.

I should probably quit while I'm ahead now but I can't see that happening; too many really cool suggestions left to try. Thanks, everybody.

Re reading this I just realized I have some of the same combo I made.Mogami shielded two conductor (i.e., three in toto) with the cheap REAN Neutrik connectors -- yes, they're directional.

DSC_0722 (2) by Mark Hardy, on Flickr

Good taste Mr Hardy..

It's just too bad I don't dust more often...

You better get that room cleaned up or you are grounded !It's just too bad I don't dust more often...

ICTWoody

No longer a junior member

Where did you pickup that cotton sleeving? I like the look.Couple more Duelund cables I made. IC’s same as my previous but with cotton sleeve, and I hestshrinked over the end of connector. Then same concept for speaker cables with raw termination

View attachment 34681

View attachment 34682

- Woody

Where did you pickup that cotton sleeving? I like the look.

- Woody

Parts Connexion 👍🏼

The company Cardas sells a very good quality solder.What do you mean by "good solder"? I have to change the RCA plugs in my phono connector box as the hex screws are lose and I ordered a set from Parts Express. Is there a brand or grade of solder I should use, it's such a small solder joint would not think it matter much.

Great thread. I went on a tear building cables the last few years as various situations permitted. Lots of headphone cables using Mogami, Canare and Van Damme product. A few XLR cables. Some interconnects with product on hand for a while waiting for me to make some time.

For headphone cables, I dress in cloth paracord sheathing. Remove the inner strands and you’re left with a colorful and durable weaved outer sleeve.

For headphone cables, I dress in cloth paracord sheathing. Remove the inner strands and you’re left with a colorful and durable weaved outer sleeve.

I need some speaker cables. Long run ~40'

Looked options

Large gauge, 8 AWG (extreme)

// smaller 12 AWG

After reading up (a good thing) and thinking (seldom a good thing) I arrived at using low surge/characteristic impedance Zo as the main design parameter.

Zo = sqrt(L/C)

It can be lowered by decreasing L or increasing C.

L is in series, signal path

C is in //

Most papers say low L is key to avoid high end roll off. Any cable phase shift is moot vs. the speaker xover.

In //

Le = 1/L1 + 1/Ln ..., if L is the same L/n

Gets smaller in //

C is the inverse

Ce = C1 + Cn, ie, the sum

I am contemplating 2 cables of 4x14 AWG per speaker. Each cable 2 x + and 2 x -.

L/4, may be smaller

Cx4 (may be larger due to separation

Offsetting and making Zo smaller

Why Zo?

At a junction the Zo on each side determines reflection and refraction (or transmission). expressed as a factor 0 to 1.

Reflection 1 = 100% reflected

Refraction 1 = 100% passed, 0% reflected

At the amp you want 100% reflected, ie, low output Z. Not distorting the output.

At speaker ideally 0 reflected/100 absorbed. Obviously not possible in a reactive circuit. In my calcs the sign will change with phase, ie, C or L load at xover.

This determines whether the effected adds or subtracts with the incident.

Yes, my head is not wired normally.

Looked options

Large gauge, 8 AWG (extreme)

// smaller 12 AWG

After reading up (a good thing) and thinking (seldom a good thing) I arrived at using low surge/characteristic impedance Zo as the main design parameter.

Zo = sqrt(L/C)

It can be lowered by decreasing L or increasing C.

L is in series, signal path

C is in //

Most papers say low L is key to avoid high end roll off. Any cable phase shift is moot vs. the speaker xover.

In //

Le = 1/L1 + 1/Ln ..., if L is the same L/n

Gets smaller in //

C is the inverse

Ce = C1 + Cn, ie, the sum

I am contemplating 2 cables of 4x14 AWG per speaker. Each cable 2 x + and 2 x -.

L/4, may be smaller

Cx4 (may be larger due to separation

Offsetting and making Zo smaller

Why Zo?

At a junction the Zo on each side determines reflection and refraction (or transmission). expressed as a factor 0 to 1.

Reflection 1 = 100% reflected

Refraction 1 = 100% passed, 0% reflected

At the amp you want 100% reflected, ie, low output Z. Not distorting the output.

At speaker ideally 0 reflected/100 absorbed. Obviously not possible in a reactive circuit. In my calcs the sign will change with phase, ie, C or L load at xover.

This determines whether the effected adds or subtracts with the incident.

Yes, my head is not wired normally.

Similar threads

- Replies

- 3

- Views

- 904

- Replies

- 15

- Views

- 2K