I don't think we have a thread on cartridge setup, so here goes. This isn't meant as any one person saying this is how you do it- I'm curious what others have learned over the years. We've all been doing this awhile and yet, at least for me, I feel that I learn a bit more every time I set up a cartridge. I'm better at it today than I was a year ago. And better then, than I was ten years ago.

Recently I've been on a bit of a cart binge, resulting from my fascination with low-mass arms and high compliance carts.

Here are some thoughts/opinions that I've acquired over the years. I can't even say they're 'right', they're just ideas I've acquired doing this over and over and over.

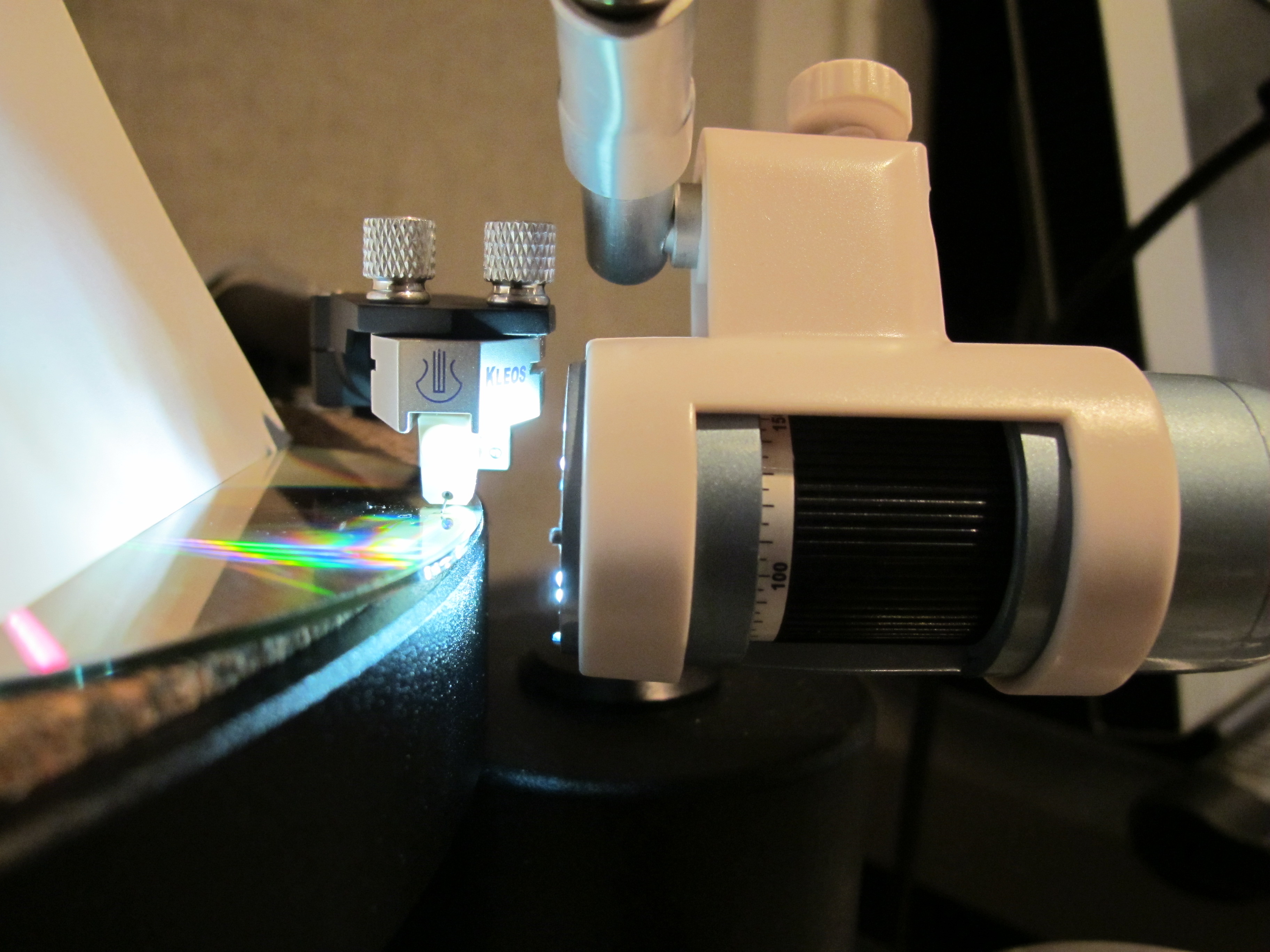

-Stylus rake angle is far more important than I used to think it was. I would spend hours trying to cure an 'edge' in the sound, or sibilance, using overhang adjustments. And then I watched a bunch of youtube videos, mostly by SoundSmith, that went into detail about how a stylus actually tracks and...lightbulb... oh, SRA is of course going to matter more than I've assumed and maybe its not an overhang problem. It's not as easy as putting the arm level, especially dealing with old carts with suspect suspensions. While I've not been using a microscope, I have been taking macro-shots of the cantilever and stylus in the groove while a record is playing, and eye-balling it to where the stylus leans just a bit forward of 90 degrees seems to work best. Though, that said, that angle of stylus in the groove with the AT cart I just put on, is achieved with the arm a bit lower than level. With the Acutex I just took off, that was achieved with the arm a bit above level. When I got it right on both, any edge disappeared. I judge mostly by how "th" sounds sound. When they're not sibilant, when they just kind of go by without being accentuated, I feel I'm in a good place. I think some call this "diction" in singing, though...maybe I'm imagining that.

-If an arm is designed to use a particular geometry, I don't assume that I know better than the people who made the arm. I use that geometry. Sometimes this means keeping my various protractors in a box and just going by overhang. Which means double checking the arm mounting distance and then checking it again. One particularly extreme case was a Tokyo Sound arm. Bearwald was not at all achievable on that arm but when I used to internet sleuthing skills to find the actual overhang numbers buried in a manual on some foreign language site... it tracked very well. Also nothing bugs me more than seeing a cart with an extreme twist to force some geometry onto an arm that was made for another one. That Steve Guttenberg dude does that on his SL-1200g and it annoys the crap out of me. Maybe that's the only reason it bugs me...HIM.

-I have a fozgometer, but none of my current tables have easy azimuth adjustment. Sometimes for my sanity I think its best to just pretend that something is right if I can't hear anything wrong. I know, I know azimuth is important. I've sat through a whole 'class' on it. But, yeah, sometimes life's too short to use shims. Just a personal opinion. Mostly it affects imaging/channel separation but in better made carts it seems that 'level' is ...well, its good enough for me. YMMV. But use a fozgometer if you have one, its super easy and does work.

-High compliance carts like low mass arms. Surprise! They really do. But they also like a bit of lateral resistance. If you have a damping trough, like the SME-V and AT-1100 do, use them! Ignore the people on the internet who say they don't do anything. They do. They help fill out the bass and they help the cart track the groove cleanly.

-Getting overhang is important but no more important than SRA, VTF, etc. Ok, maybe its more important than Azimuth.

-Having the right tools means EVERYTHING. From protractors, to digital scales, to some way to magnify the stylus in the groove to rough-in SRA (I use a camera with a macro lens but also have a USB microscope), to the TWEEZERS you use to push the tags onto the pins, or reverse. I have a VERY nice set of needle-nose tweezers that I have left over from when I built tiny model ships. They're life, and cart, savers.

I don't mean to write these all like they're laws or rules...they're just my opinions. I would love to hear the opinions of others, even if they totally disagree.

Recently I've been on a bit of a cart binge, resulting from my fascination with low-mass arms and high compliance carts.

Here are some thoughts/opinions that I've acquired over the years. I can't even say they're 'right', they're just ideas I've acquired doing this over and over and over.

-Stylus rake angle is far more important than I used to think it was. I would spend hours trying to cure an 'edge' in the sound, or sibilance, using overhang adjustments. And then I watched a bunch of youtube videos, mostly by SoundSmith, that went into detail about how a stylus actually tracks and...lightbulb... oh, SRA is of course going to matter more than I've assumed and maybe its not an overhang problem. It's not as easy as putting the arm level, especially dealing with old carts with suspect suspensions. While I've not been using a microscope, I have been taking macro-shots of the cantilever and stylus in the groove while a record is playing, and eye-balling it to where the stylus leans just a bit forward of 90 degrees seems to work best. Though, that said, that angle of stylus in the groove with the AT cart I just put on, is achieved with the arm a bit lower than level. With the Acutex I just took off, that was achieved with the arm a bit above level. When I got it right on both, any edge disappeared. I judge mostly by how "th" sounds sound. When they're not sibilant, when they just kind of go by without being accentuated, I feel I'm in a good place. I think some call this "diction" in singing, though...maybe I'm imagining that.

-If an arm is designed to use a particular geometry, I don't assume that I know better than the people who made the arm. I use that geometry. Sometimes this means keeping my various protractors in a box and just going by overhang. Which means double checking the arm mounting distance and then checking it again. One particularly extreme case was a Tokyo Sound arm. Bearwald was not at all achievable on that arm but when I used to internet sleuthing skills to find the actual overhang numbers buried in a manual on some foreign language site... it tracked very well. Also nothing bugs me more than seeing a cart with an extreme twist to force some geometry onto an arm that was made for another one. That Steve Guttenberg dude does that on his SL-1200g and it annoys the crap out of me. Maybe that's the only reason it bugs me...HIM.

-I have a fozgometer, but none of my current tables have easy azimuth adjustment. Sometimes for my sanity I think its best to just pretend that something is right if I can't hear anything wrong. I know, I know azimuth is important. I've sat through a whole 'class' on it. But, yeah, sometimes life's too short to use shims. Just a personal opinion. Mostly it affects imaging/channel separation but in better made carts it seems that 'level' is ...well, its good enough for me. YMMV. But use a fozgometer if you have one, its super easy and does work.

-High compliance carts like low mass arms. Surprise! They really do. But they also like a bit of lateral resistance. If you have a damping trough, like the SME-V and AT-1100 do, use them! Ignore the people on the internet who say they don't do anything. They do. They help fill out the bass and they help the cart track the groove cleanly.

-Getting overhang is important but no more important than SRA, VTF, etc. Ok, maybe its more important than Azimuth.

-Having the right tools means EVERYTHING. From protractors, to digital scales, to some way to magnify the stylus in the groove to rough-in SRA (I use a camera with a macro lens but also have a USB microscope), to the TWEEZERS you use to push the tags onto the pins, or reverse. I have a VERY nice set of needle-nose tweezers that I have left over from when I built tiny model ships. They're life, and cart, savers.

I don't mean to write these all like they're laws or rules...they're just my opinions. I would love to hear the opinions of others, even if they totally disagree.