SP12B would be a nice choice, IMO, for what the OP wants to do...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Altec 12/15 'alternative'...

- Thread starter gable

- Start date

Where-ish do you live?

A long-term loan of something EV-ish could, perhaps, be arranged

Oh, you know what could (?!?) be interesting?

These. 😏

A pair of EV "Wolverine" LS-15 OEM, branded RCA, and - at some point (not by me!) - de-whizzered.

For comparison, here're a pair of normal LS-15s avec their whizzers.

info on the LS8, LS12(A), and LS15 from EV at https://www.electrovoice.com/binary/LS8, LS12A and LS15 EDS.pdf

Note that the sensitivities are given relative to the EIA specification (1 mW at 30 feet, or something like that); add ca. 50 dB for 1watt @ 1 meter. This guy sez 49 dBEIA sensitivity?

I live in Texas, South of Austin, in the HOT AS <expletive> BELT.

The LS15's look interesting, I'm not familiar with them. Have you tried them in your system?

I'm pretty sure I have a pair of SP12B gathering dust in the audio closet if you're interested.

Definitely, PM me details please.

I experimented with Beymas when I was in Manila because I knew the dealer and Altecs are much harder to come by there.

Since my return, I've been tempted to try modern drivers like Eminence, Faital Pro, etc., but these modern drivers aren't really cheap. As evidenced by the pictures posted, there are still unexplored classic alnico/paper cone drivers from EV, Jensen, etc. I've also seen vintage Pioneer 12" woofers on eBay that may have potential.

Happy hunting!

Since my return, I've been tempted to try modern drivers like Eminence, Faital Pro, etc., but these modern drivers aren't really cheap. As evidenced by the pictures posted, there are still unexplored classic alnico/paper cone drivers from EV, Jensen, etc. I've also seen vintage Pioneer 12" woofers on eBay that may have potential.

Happy hunting!

There were some very fine early Pioneer/Fukuin drivers -- one may sometimes find them in the US bearing the brand names of US catalog houses. Just sayin'...

Pioneer/Exclusive/TAD スピーカーユニット/ネットワーク一覧 パイオニア/エクスクルーシブ

Ditto Matsushita/Panasonic/National

Technics/National/Panasonic スピーカーユニット一覧 テクニクス/ナショナル/パナソニック

Pioneer/Exclusive/TAD スピーカーユニット/ネットワーク一覧 パイオニア/エクスクルーシブ

Ditto Matsushita/Panasonic/National

Technics/National/Panasonic スピーカーユニット一覧 テクニクス/ナショナル/パナソニック

So I got a pair of SP12B's from @rusomon. They were delivered last week, and the pictures don't do them justice. They are in fantastic shape, dcr is good.

Now, with those acquired I started looking for information for what size box to build. I found an EV bulletin, #10a iirc and read through it. I'll attach it here as well.

So based on the doc I'm building a ~4cu/ft box, the port is causing me some headache. Maybe I'm reading that section incorrectly. I came up with a 2" tall, 4.25" wide, 7.5" deep port. Don't ask me how, but that's what the piece of paper on my desk says after I read through it and 'mathed' it out like a champ.

Any insights would be awesome...fairly certain I did something wrong.

Now, with those acquired I started looking for information for what size box to build. I found an EV bulletin, #10a iirc and read through it. I'll attach it here as well.

So based on the doc I'm building a ~4cu/ft box, the port is causing me some headache. Maybe I'm reading that section incorrectly. I came up with a 2" tall, 4.25" wide, 7.5" deep port. Don't ask me how, but that's what the piece of paper on my desk says after I read through it and 'mathed' it out like a champ.

Any insights would be awesome...fairly certain I did something wrong.

Attachments

Hmm.... I am no expert, but the depth of 7.5" seems odd to me. In my experience, the cabinet designs of the period made do with a suitable hole in the baffle, and no 'depth' beyond the thickness of the wood itself. The deeper port designs came when the monkey coffins got too small to just cut a hole into.

Taking the advertised "40 to 50 cycles" resonance of the SP12B, and a 4 cu. ft. box, the 60's Altec Enclosure Plans indicate a port of up to 20 sq. inches, which I would cut as 2 by 10 inches. Admittedly, Altec and EV may have had differing ideas about box tuning, but the underlying physics hold... and I find the Altec chart a bit easier to read.

Have you looked at the EV Marquis? And with respect to mathing it out - I recommend Wolfram Alpha as a useful calculator with on-the-fly unit conversions, as in this example where I gave it inches and asked for cubic feet in return.

Taking the advertised "40 to 50 cycles" resonance of the SP12B, and a 4 cu. ft. box, the 60's Altec Enclosure Plans indicate a port of up to 20 sq. inches, which I would cut as 2 by 10 inches. Admittedly, Altec and EV may have had differing ideas about box tuning, but the underlying physics hold... and I find the Altec chart a bit easier to read.

Have you looked at the EV Marquis? And with respect to mathing it out - I recommend Wolfram Alpha as a useful calculator with on-the-fly unit conversions, as in this example where I gave it inches and asked for cubic feet in return.

I just bought a pair of Bozak B-199a woofers and will likely test those in the same cabinets I'm making for the SP12-B's. I plan to make the baffle and rear panels removable, so I can swap a new baffle with a port if needed, or leave the rear off for open back. If all goes well, and who knows if it will, I will build the cabinets in two weeks. I've got a bit of time off and my dad is coming down to stay with us for a couple days.

I'll take a pic of my on paper sketch of the cabinet and post it later. Basically, it's made from 1" Baltic Birch, 1/2" laminated together as I can get 1/2" ~5min from the house. I will likely put some CLD material on the side walls before I add the denim insulation, to help make those panels less resonant. My hope is to mitigate the need for any bracing across the internal chamber. If I need to add bracing I will.

I'm also thinking about making the bottom panel ~1.5", so I can cut in some mounting points for feet of some sort.

I'll take a pic of my on paper sketch of the cabinet and post it later. Basically, it's made from 1" Baltic Birch, 1/2" laminated together as I can get 1/2" ~5min from the house. I will likely put some CLD material on the side walls before I add the denim insulation, to help make those panels less resonant. My hope is to mitigate the need for any bracing across the internal chamber. If I need to add bracing I will.

I'm also thinking about making the bottom panel ~1.5", so I can cut in some mounting points for feet of some sort.

So, I've scored some EC 175's and they're on the way, thank you @gavcnew !

I've got some time off next week and am planning to build some cabinets that I can swap baffles and rear panels in to try the B-199A's, and the SP-12B's. To that end, I pulled out a pair of mast_mutter autoformers, and some various other parts to try different crossover points.

Hopefully I can get all the various bits together this weekend so I have time to knock out the cabinets and do some testing/listening late next week, when I'm off work.

I've got some time off next week and am planning to build some cabinets that I can swap baffles and rear panels in to try the B-199A's, and the SP-12B's. To that end, I pulled out a pair of mast_mutter autoformers, and some various other parts to try different crossover points.

Hopefully I can get all the various bits together this weekend so I have time to knock out the cabinets and do some testing/listening late next week, when I'm off work.

Good looking crossover pieces there including the board. I need to build me something like those.

Cheap Ikea cutting board, cut down to size!

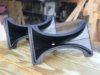

I was able to slice off a bit of time in the shop this afternoon/evening. I painted the Emilar bowtie horns this morning with a few fresh coats of black 'hammertone'. This afternoon I got all the components for the two lf cabs cut, and started gluing up the pieces to make the 1" thick panels.

My plan is to sneak out to the shop each day of this long weekend and keep chipping away at the to-do list.

I have a quick sketch, and cut list I'm working from, but I'm shooting from the hip a little bit as I'm modifying the cabinets a bit to try and make them look nicer and be a bit heavier, because... well, who knows why?!

A few pics:

Look at that, he made a pile of plywood, then spray painted some metal hunks..

Momma always said I had a special purpose... now we know what it is.

My plan is to sneak out to the shop each day of this long weekend and keep chipping away at the to-do list.

I have a quick sketch, and cut list I'm working from, but I'm shooting from the hip a little bit as I'm modifying the cabinets a bit to try and make them look nicer and be a bit heavier, because... well, who knows why?!

A few pics:

Look at that, he made a pile of plywood, then spray painted some metal hunks..

Momma always said I had a special purpose... now we know what it is.

I used some rust-o-leum black hammertone spray paint I got at the lumber yard. I cleaned the horns real well and took my time painting them, put 2-3 light coats on. They look decent from a few feet away, and are at least even. They had a lot of little dings and spots on them previously.

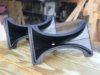

I made some nice progress in the shop today. I got all the panels glued together and most of them trimmed to their final dimensions. I got the cleats installed on the bottom panels and did some quick and dirty recesses for the Ikea feet I plan on using. Tomorrow I'll glue up the boxes and get the rest of the cleats installed, then hopefully start working on the baffles.

The top is 3 layers of 12mm baltic birch, all the other panels are 2 layers. I may put some CLD material on the side panels to hopefully prevent me needing to install a brace(s). Then I'll use some denim insulation on the sides, top and bottom panels.

So far progress is moving along very well, and should allow me to spend some time tuning and listening late next week.

The view from the front, the top panel overhangs the sides and front, I may chamfer the top edges on the sides, we'll see how I feel when I get to the point:

The top is 3 layers of 12mm baltic birch, all the other panels are 2 layers. I may put some CLD material on the side panels to hopefully prevent me needing to install a brace(s). Then I'll use some denim insulation on the sides, top and bottom panels.

So far progress is moving along very well, and should allow me to spend some time tuning and listening late next week.

The view from the front, the top panel overhangs the sides and front, I may chamfer the top edges on the sides, we'll see how I feel when I get to the point:

More progress today, I got the cabinets glued up, and got all the cleats glued in. I also was able to get most of the cabinets mostly sanded. I think I'll do a bit of sanding tomorrow, then put a few coats of finish on. While that's dryng, I'll trim the baffles and make the driver cut-outs.

The cleats are mostly made of scrap from previous projects. You can see some circle cut-outs on the rear cleats. Those are pieces leftover from cutting my lab desk tops down to size during my recent home office move.

For finish I'm thinking a few coats of danish oil and a bit of wax. These are prototypes, but will likely live in the bedroom or living room for awhile, so I want them to look nice.

The cleats are mostly made of scrap from previous projects. You can see some circle cut-outs on the rear cleats. Those are pieces leftover from cutting my lab desk tops down to size during my recent home office move.

For finish I'm thinking a few coats of danish oil and a bit of wax. These are prototypes, but will likely live in the bedroom or living room for awhile, so I want them to look nice.

Similar threads

- Replies

- 2

- Views

- 430

- Replies

- 25

- Views

- 2K

- Replies

- 39

- Views

- 6K